GENUS

DESIGN: KOMPLOT DESIGN

MANUFACTURER: HOWE

2002

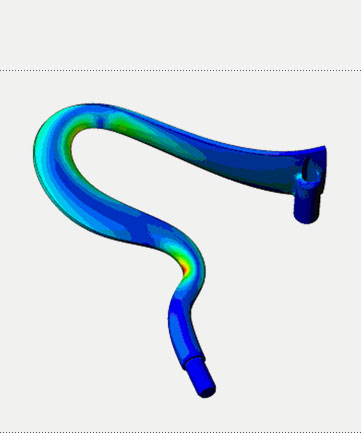

THE ARMREST, THE CONNECTION BETWEEN THE FRAME AND THE SEATING-SHELL AS WELL AS THE STACKING TRAY ARE ALL MANUFACTURED IN PLASTIC. THE ARMREST IS MANUFACTURED WITH AN ADVANCED PLASTIC INJECTION MOLDING TECHNIQUE, WHERE THE CORE MATERIAL IS MOLDED INTO THE SOFT SURFACE MATERIAL. THE PLASTIC SEAT-TO-FRAME CONNECTION IS MANUFACTURED OF A SPECIAL TOUGH TRANSPARENT PLASTIC MATERIAL AND IS GLUED ONTO THE SEATING SHELL USING A GLUE, WHICH IS HARDENING WHEN EXPOSED TO UV LIGHT. THE STACKING TRAY SERVES SEVERAL PURPOSES: PROVIDING SEPARATION BETWEEN CHAIRS WHEN STACKED AND IS PART OF THE ROW-CONNECTOR FINALLY IT PROVIDES SUPPORT FOR THE JUNCTION.

MOLGARD APS PARTICIPATED IN THE DEVELOPMENT OF ALL THE PLASTIC PARTS. INCLUDING 3D CAD FILES, STRENGTH CALCULATIONS, ANALYSES OF MANUFACTURING COSTS AND IDENTIFICATION OF APPROPRIATE SUB-SUPPLIERS.

Be First to Comment